Amirhossein Omidvar, Carlos D Gerardo, Robert Rohling, Edmond Cretu, Antony J Hodgson

Amirhossein Omidvar, Carlos D Gerardo, Robert Rohling, Edmond Cretu, Antony J Hodgson

Conventional ultrasound (US) probes are rigid. The rigidity has several drawbacks including acoustic energy loss and artifacts (due to interface mismatch between skin and probe), patient discomfort, limited field of view, and operator dependency. Many of these problems could potentially be addressed with a flexible US array that can conform to body parts.

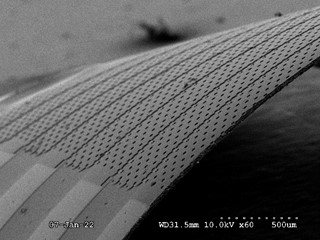

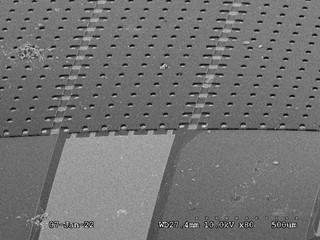

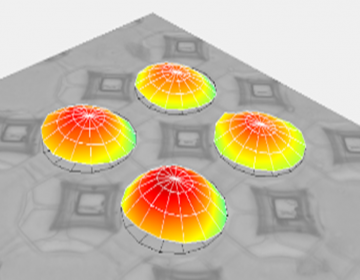

Traditional piezoelectric-based US probes are limited in terms of bandwidth, efficiency, high-resolution imaging, and integration with electronics compared to their recently matured counterpart called capacitive micromachined ultrasonic transducers (CMUTs). CMUTs are essentially drum-like microstructures that can generate or sense ultrasound through a variable electrostatic field. Thanks to flexibility of microfabrication techniques, CMUTs can be made using polymers. This opens many possibilities, one of which is flexible ultrasound probes. We present a novel fabrication technique for flexible CMUTs (FlexCMUT) that is simple, inexpensive, robust, and can potentially be used for wearable medical imaging applications.

Congratulations to Farhad Omidvar for a CMC excellence award: Microsystems Fabrication

Conference paper: https://ieeexplore.ieee.org/document/9593645