Becoming a member

Fee structure (fiscal 2024-2025)

ANF Store

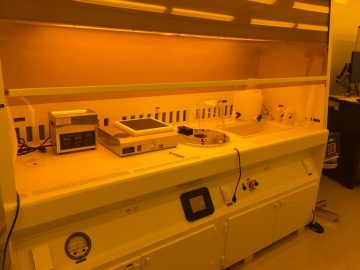

Renovated Cleanroom

The facility’s cleanroom is contained within Labs 446 in Brimacombe’s AMPEL wing. It was fully renovated in 2019 to occupy about 50 m2 with 2 yellow rooms (ISO5 and ISO6) and a large white room (ISO6). Many new tools and instruments were bought to replace aging older equipment.

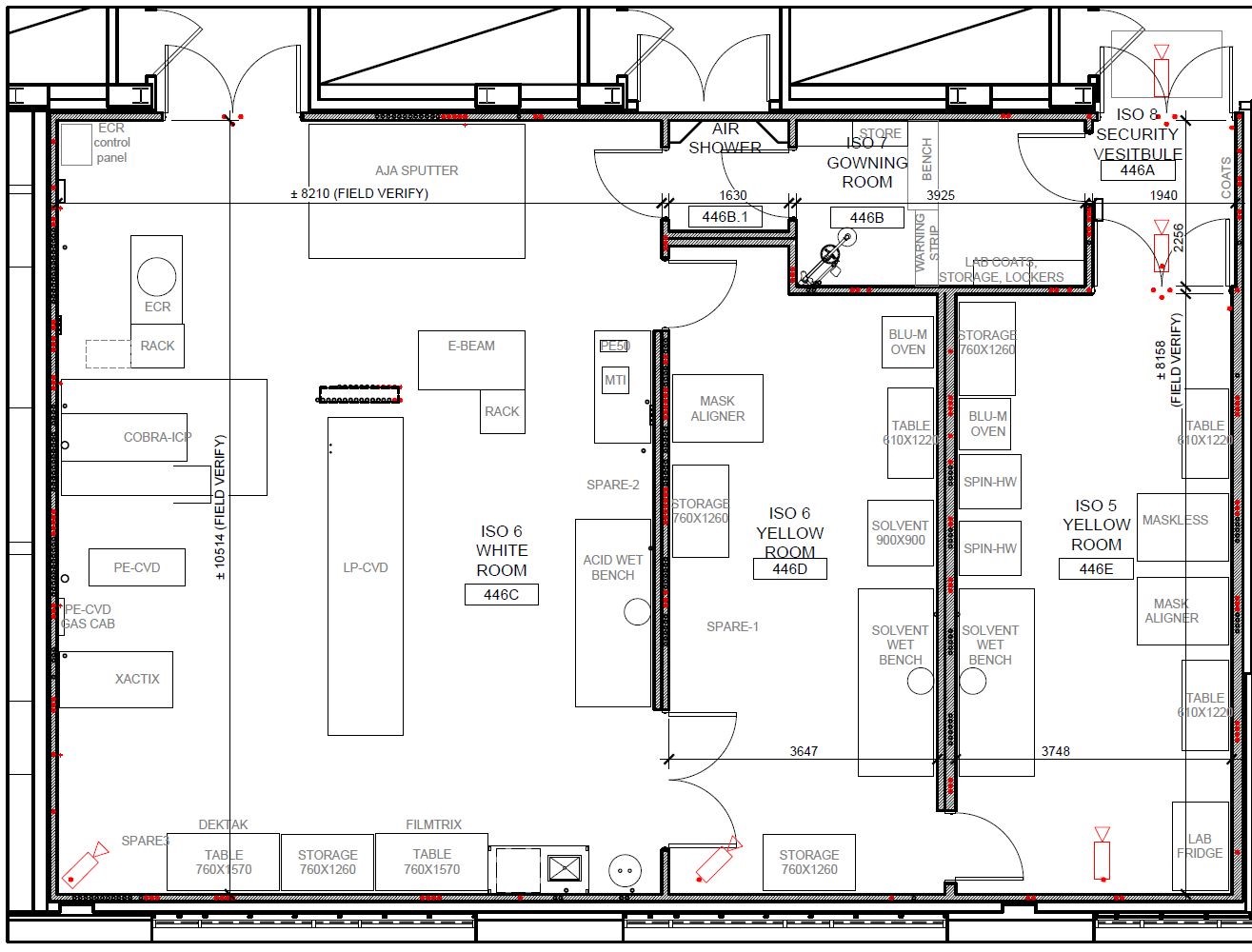

The drawing in the figure below shows the cleanroom layout. You will find that the location of some of the tools is different than shown.

The renovated cleanroom layout – Labs 446