Standard operating procedure Rev 02, O4/21 (beta version)

Author(s):

Rev. 01: Becky Lin

Rev. 02 (under construction)

Superusers:

Dr. Matthew Mitchell

Content:

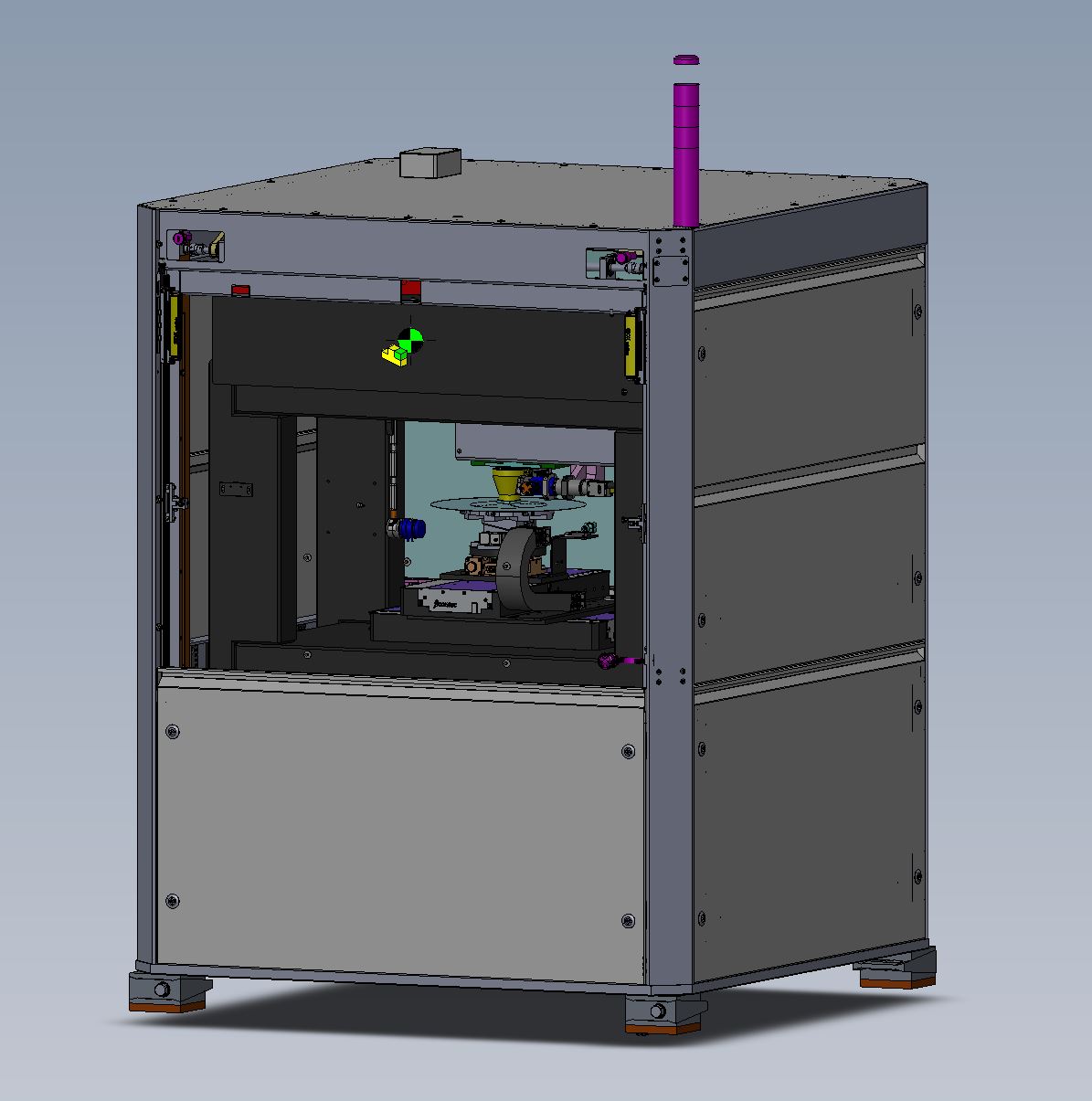

This tool allows 3D, 2 photon lithography. It’s main purpose is to create waveguides to mate different photonic circuits together. The tool will be available soon.